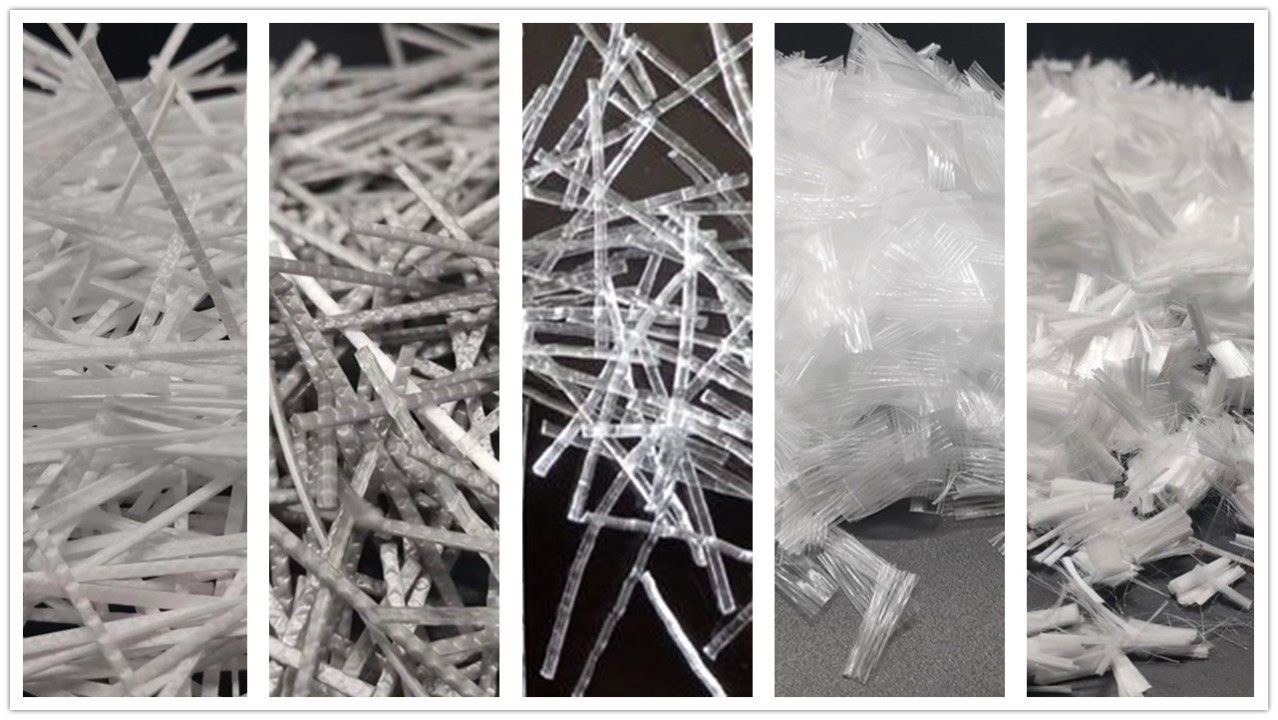

Premco Constructional MacroFiber

REPLACEMENT OF STEEL FIBER, STEEL MESH

INCREASE OF CONCRETE TENSILE STRENGTH IN BENDING

REDUCTION OF CRACKING

IT Affects

INCREASES TENSILE STRENGTH IN BENDING

□ REDUCES SHRINKAGE WHILE CONCRETE

HARDENING

□ INCREASES THE RESIDUAL STRENGTH

(AFTER CRACKS FORMATION)

□ INCREASES PLASTICITY OF DESTRUCTION

□ REDISTRIBUTES BREAKING LOADS

□ INCREASES CRACKING RESISTANCE

OF CONCRETE CONSTRUCTIONS

□ REMOVES THE RISK OF CORROSION

□ ALLOWS TO GET RID OF CONSTRUCTION

REINFORCEMENT WITH STEEL MESH

□ INCREASES FIRE RESISTANCE

OF CONCRETE CONSTRUCTION

□ SAFER, EASIER AND CHEAPER

TO WORK THAN STEEL

Economic Applicability

To achieve the same results of strength of the slab, it is enough to use 6-6.5 times less polymer fiber than steel fiber.

APPLYING OF CONCRETE FLOOR, AREA 3000 m2 (~450 m3 of concrete)

| Steel Fiber | Premco MacroFiber | |

| Consumption per m3 of concrete | 20 kg/m3

of concrete |

3,3 kg/m3

of concrete |

| Quantity of fiber | 9000kg | 1500 kg |

| Quantity of fibers per m3 | ~ 64 000 pcs | ~ 160 000 pcs |

Technical Information

350 °C

Absorption zero

Q-ty in 1 kg, more than, pcs 50 000 (for length 40 mm)

| Fiber length | 25/40/55 mm (±2mm) |

| The equivalent diameter of a single Fiber | 0,8 mm |

| Tensile strength | 400 MPa |

| Modulus of elasticity | 6,0 GPa |

| Consistency of concrete with 4 kg/m3 of Premco MacroFiber |

VeBe time 6 sec |

| Material | Polyolefin 100% |

| Density | 0,91 g/cm3 |

| Colour | graphite |

| Alkali and chemical resistance | excellent |

| Melting point | 160 °C |

| Ignition point | 350 °C |

| Absorption | zero |

| Q-ty in 1 kg, more than, pcs | 50 000 (for length 40 mm) |

INDUSTRIAL FLOORS

(WITH ADDITIONAL

TOPPING)

SHOTCRETE

(TUNNELS, SUBWAYS)

ROAD SURFACES,

CAR PARKINGS

PREFABRICATED

ELEMENTS (SLABS, BEAMS,

PRECAST UNITS)

Usage

Premco structural macrofiber can be added to concrete mix at any time before the application of concrete. It is generally recommended to add any fibrous material at a concrete plant during dosing. Fibers must be mixed with concrete for a minimum of three (3) to five (5) minutes with a maximum mixing speed, depending on the type of mixer to ensure complete dispersion and constancy. Add other impurities regardless

of the fiber added. Synthetic microfiber Premco is compatible with all additives.

Dosage

The dosage rate will vary depending on the requirements for reinforcing concrete and for providing equivalent tensile and bending resistance. The recommended dosage range for Premco Macrofiber is 2 to 8 kg/m3. When used in the proper dosage, Premco is an option to replace steel shrink mesh, and metal fiber or significantly reduce steel bar reinforcement. It is a safe and easy-to-use alternative reinforcement system that is resistant to corrosion and alkali.

Contact

Call Or whatsapp Us for all your projects need At

Offices

Follow Us

Copyright © 2024 Premco ®